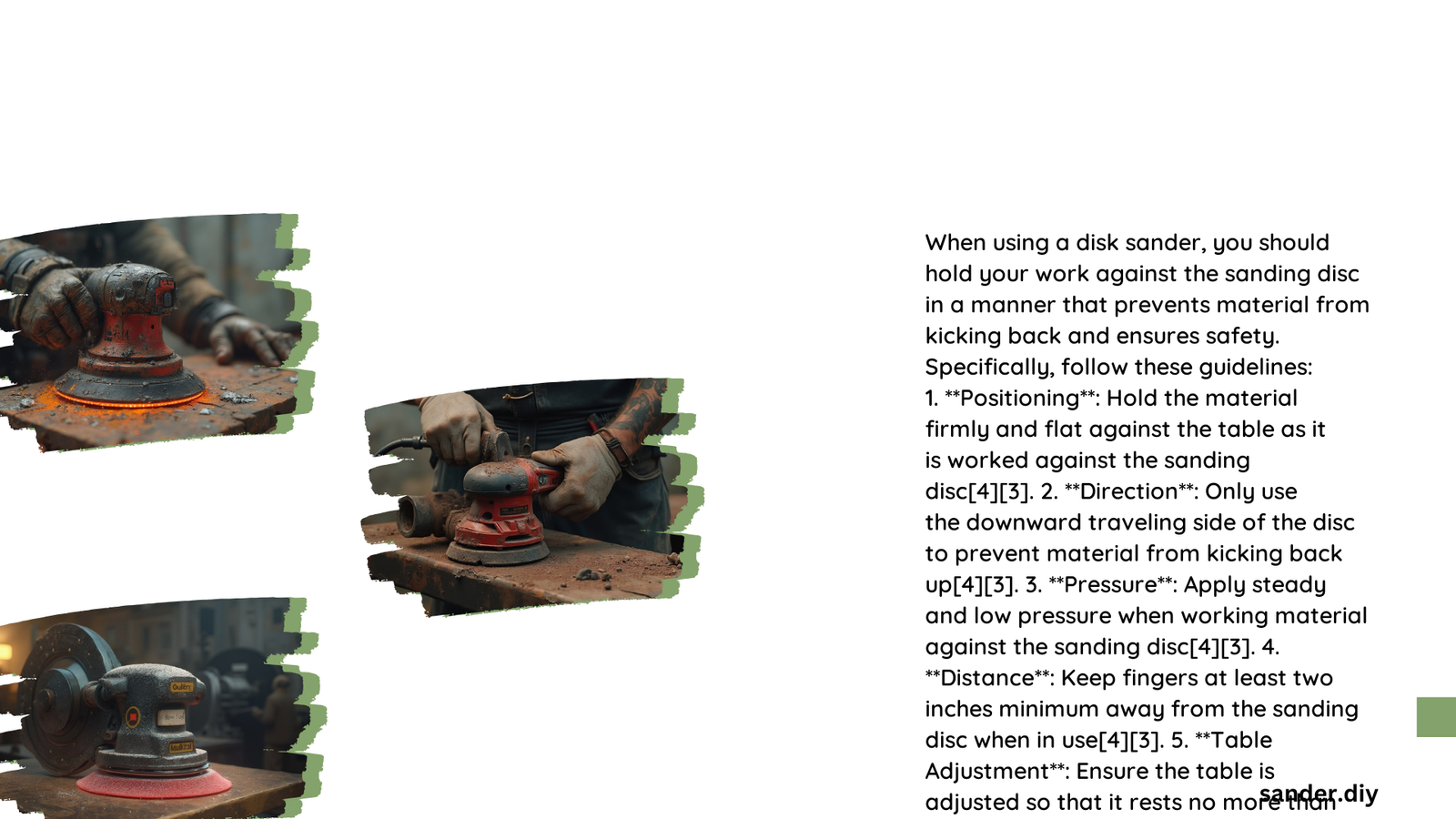

Disk sanders are powerful woodworking tools that require precise technique and careful handling. When using a disk sander, professionals understand that holding the workpiece correctly is crucial for achieving smooth, accurate surfaces. The key lies in maintaining consistent pressure, controlling the angle, and understanding the sander’s rotational dynamics to prevent material damage and ensure professional-grade results.

What Makes Disk Sander Workpiece Positioning Critical?

Proper workpiece positioning on a disk sander involves multiple technical considerations that directly impact the quality of your sanding outcome. Understanding these nuanced techniques can transform your woodworking precision.

How Should You Approach Workpiece Contact?

- Table Alignment

- Position workpiece parallel to sander’s table

- Ensure stable, flat contact surface

-

Use miter gauge for complex angles

-

Pressure Management

- Apply firm, consistent pressure

- Avoid excessive force

- Maintain steady hand movement

What Are the Fundamental Sanding Techniques?

| Technique | Description | Key Considerations |

|---|---|---|

| Angle Control | Adjust table up to 45 degrees | Use protractor or built-in angle guides |

| Rotation Direction | Sand with disc’s downward rotation | Prevents workpiece lifting |

| Speed Management | Maintain consistent sander RPM | Typically 1000-2000 RPM |

Why Does Workpiece Orientation Matter?

Correct workpiece orientation prevents several critical issues:

– Minimizes uneven sanding surfaces

– Reduces potential material damage

– Prevents dangerous kickback scenarios

– Ensures smoother finishing results

How Can You Enhance Sanding Precision?

Professional woodworkers recommend:

– Using auxiliary support for larger pieces

– Wearing appropriate safety gear

– Maintaining clean, sharp sanding discs

– Practicing consistent hand movements

What Technical Factors Influence Sanding Quality?

Technical considerations include:

– Abrasive grit selection

– Workpiece material hardness

– Sander motor specifications

– Environmental workshop conditions

Can You Prevent Common Sanding Mistakes?

Avoid these critical errors:

– Applying inconsistent pressure

– Sanding against disc rotation

– Neglecting workpiece support

– Ignoring personal safety protocols

What Safety Precautions Should You Follow?

- Wear safety glasses

- Use dust collection systems

- Maintain proper workshop ventilation

- Keep hands away from active sanding surface

- Disconnect power before changing discs

Conclusion

Mastering disk sander techniques requires practice, understanding mechanical principles, and developing muscle memory. By focusing on precise workpiece positioning, pressure control, and safety protocols, woodworkers can achieve professional-grade results consistently.