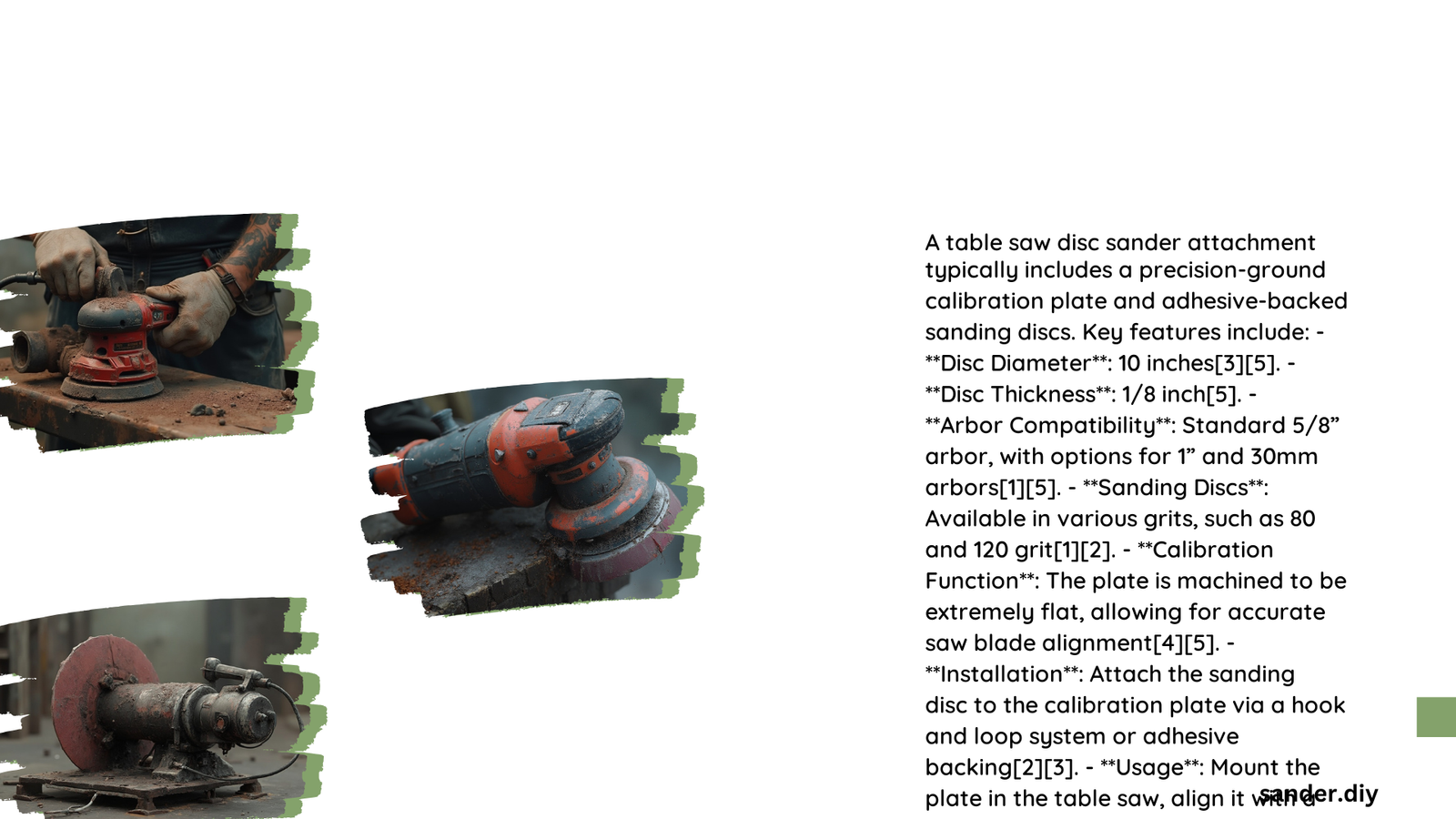

A table saw disc sander attachment is a versatile tool that transforms your table saw into a powerful sanding station. It typically consists of a circular disc with a sandpaper surface that attaches to the table saw’s arbor. This attachment allows woodworkers to perform precise sanding operations on various materials, enhancing the functionality of their table saw and streamlining their workflow.

What Are the Key Features of a Table Saw Disc Sander Attachment?

Table saw disc sander attachments come with several important features:

- Compatibility: Designed to fit standard table saw arbors (usually 5/8 inch)

- Size: Typically 10 inches in diameter to match common table saw blade sizes

- Material: Often made of durable metal like steel or aluminum

- Backing: May include hook-and-loop or PSA (Pressure-Sensitive Adhesive) for easy sandpaper changes

- Precision: Some models offer high flatness tolerance for accurate sanding

How Does a Table Saw Disc Sander Attachment Work?

The table saw disc sander attachment operates by utilizing the rotational power of your table saw. Here’s a step-by-step explanation:

- The attachment is secured to the table saw’s arbor, replacing the regular saw blade.

- Sandpaper is affixed to the disc’s surface using either a hook-and-loop system or adhesive backing.

- When the table saw is turned on, the disc rotates, creating a large sanding surface.

- Users can then press workpieces against the spinning disc to sand them.

What Are the Benefits of Using a Table Saw Disc Sander Attachment?

Using a table saw disc sander attachment offers several advantages:

- Versatility: Transforms your table saw into a dual-purpose tool

- Space-saving: Eliminates the need for a separate disc sander

- Precision: Allows for accurate and controlled sanding operations

- Cost-effective: More affordable than purchasing a standalone disc sander

- Efficiency: Enables quick transitions between cutting and sanding tasks

What Safety Precautions Should Be Taken When Using a Table Saw Disc Sander Attachment?

Safety is paramount when using any power tool. Here are essential safety measures for using a table saw disc sander attachment:

- Always wear safety glasses and a dust mask.

- Ensure the attachment is securely fastened to the arbor before use.

- Sand only on the downward-rotating side of the disc to prevent workpiece kickback.

- Keep hands and fingers away from the spinning disc.

- Use push blocks or sticks when sanding small pieces.

- Disconnect power when changing sandpaper or making adjustments.

How to Choose the Right Table Saw Disc Sander Attachment?

Selecting the appropriate attachment depends on several factors:

| Factor | Consideration |

|---|---|

| Compatibility | Ensure it fits your table saw’s arbor size |

| Size | Match the diameter to your saw’s blade capacity |

| Material Quality | Look for durable materials like steel or aluminum |

| Flatness Tolerance | Higher precision for more accurate sanding |

| Backing Type | Choose between hook-and-loop or PSA for sandpaper attachment |

What Are the Common Sizes and Specifications for Table Saw Disc Sander Attachments?

Table saw disc sander attachments typically come in standard sizes:

- Diameter: Most common is 10 inches, matching standard table saw blade sizes

- Arbor Hole: Usually 5/8 inch to fit standard table saw arbors

- Thickness: Varies, but generally between 1/8 to 1/4 inch

- Weight: Ranges from 1 to 3 pounds, depending on material and size

How to Install a Table Saw Disc Sander Attachment?

Installing a table saw disc sander attachment is straightforward:

- Unplug the table saw for safety.

- Remove the existing saw blade and any blade guards.

- Clean the arbor and flange to ensure a secure fit.

- Place the disc sander attachment onto the arbor.

- Secure it with the arbor nut, tightening it firmly.

- Attach the desired grit sandpaper to the disc surface.

- Reinstall any necessary guards or safety features.

- Perform a test run to ensure proper installation and operation.

What Maintenance Is Required for a Table Saw Disc Sander Attachment?

Proper maintenance ensures longevity and optimal performance:

- Regularly clean the disc surface to remove dust and debris.

- Check for any warping or damage to the disc.

- Ensure the attachment remains securely fastened to the arbor.

- Replace sandpaper as needed to maintain effective sanding.

- Periodically check and adjust the table saw’s alignment for accurate results.

How to Achieve Optimal Results with a Table Saw Disc Sander Attachment?

To get the best results from your table saw disc sander attachment:

- Choose the Right Grit: Start with coarser grits for material removal, then progress to finer grits for smoothing.

- Maintain Consistent Pressure: Apply even pressure to avoid uneven sanding.

- Keep the Workpiece Moving: Avoid holding the workpiece in one spot to prevent gouging.

- Use the Miter Gauge: For precise angle sanding, utilize your table saw’s miter gauge.

- Sand on the Downstroke: Always sand on the side of the disc rotating downward to prevent kickback.

What Are the Limitations of a Table Saw Disc Sander Attachment?

While versatile, table saw disc sander attachments have some limitations:

- Limited to the size of the disc (typically 10 inches)

- May not be as powerful as dedicated disc sanders

- Requires removal of the saw blade, which can be inconvenient for frequent switching

- Not suitable for heavy-duty sanding tasks that require prolonged use

How Does a Table Saw Disc Sander Attachment Compare to a Standalone Disc Sander?

Here’s a comparison between a table saw disc sander attachment and a standalone disc sander:

| Feature | Table Saw Attachment | Standalone Disc Sander |

|---|---|---|

| Cost | Generally less expensive | More expensive |

| Space Required | Uses existing table saw | Requires additional space |

| Power | Limited by table saw motor | Dedicated motor, potentially more powerful |

| Versatility | Dual-purpose tool | Single-purpose tool |

| Size Options | Limited to table saw capacity | Various sizes available |

| Convenience | Requires blade change | Always ready for use |

By understanding these aspects of table saw disc sander attachments, woodworkers can make informed decisions about incorporating this versatile tool into their workshop setup, enhancing their sanding capabilities while maximizing the utility of their table saw.

References:

1. ShopSmith Forums

2. The Honest Carpenter on YouTube

3. Infinity Tools