When Using an Electric Sander Be Sure To: Comprehensive Safety and Performance Guide

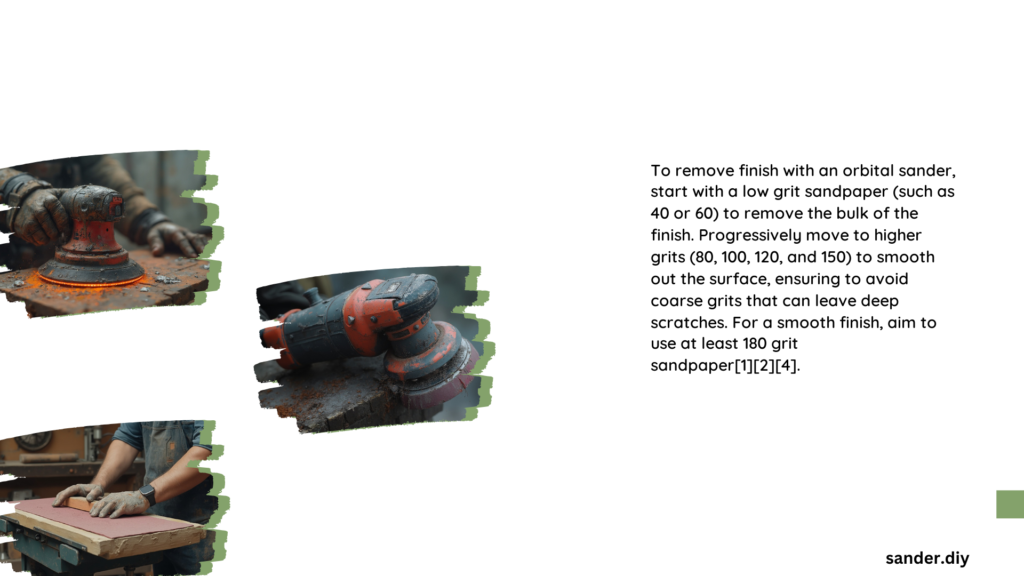

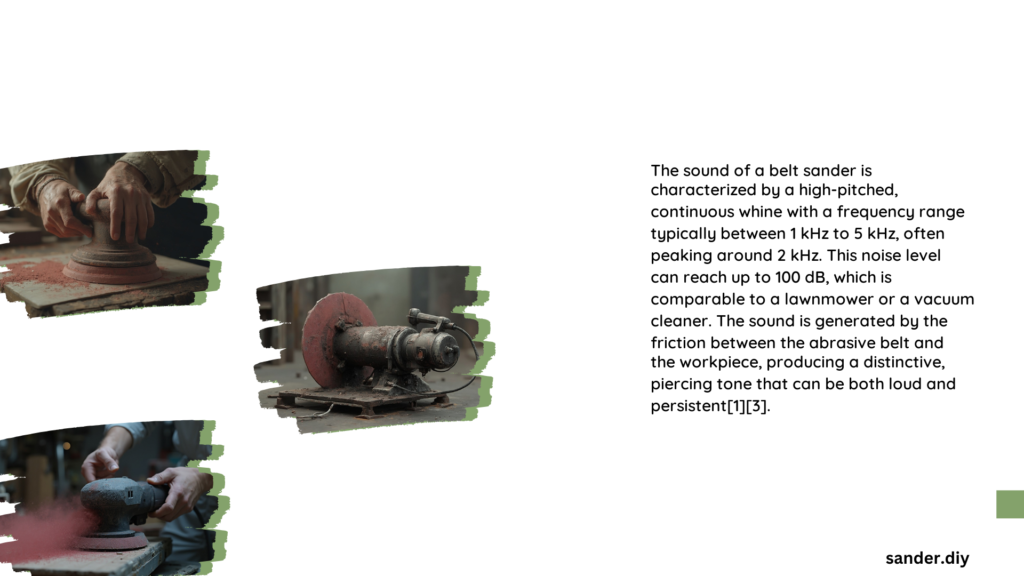

Electric sanders are powerful woodworking tools that demand careful handling and precise technique. When using an electric sander, operators must prioritize personal safety, understand proper operational techniques, and maintain equipment integrity to prevent accidents, ensure optimal performance, and achieve superior finishing results. This comprehensive guide ...

Read more