Orbital sanders provide a powerful and precise method for smoothing and preparing cast iron surfaces, offering craftsmen and metalworkers an efficient solution for rust removal, surface leveling, and finishing. By understanding the right techniques, selecting appropriate sanders, and using correct grit progression, professionals can transform rough cast iron surfaces into smooth, refined workpieces with minimal effort and maximum precision.

What Makes Orbital Sanders Effective for Cast Iron?

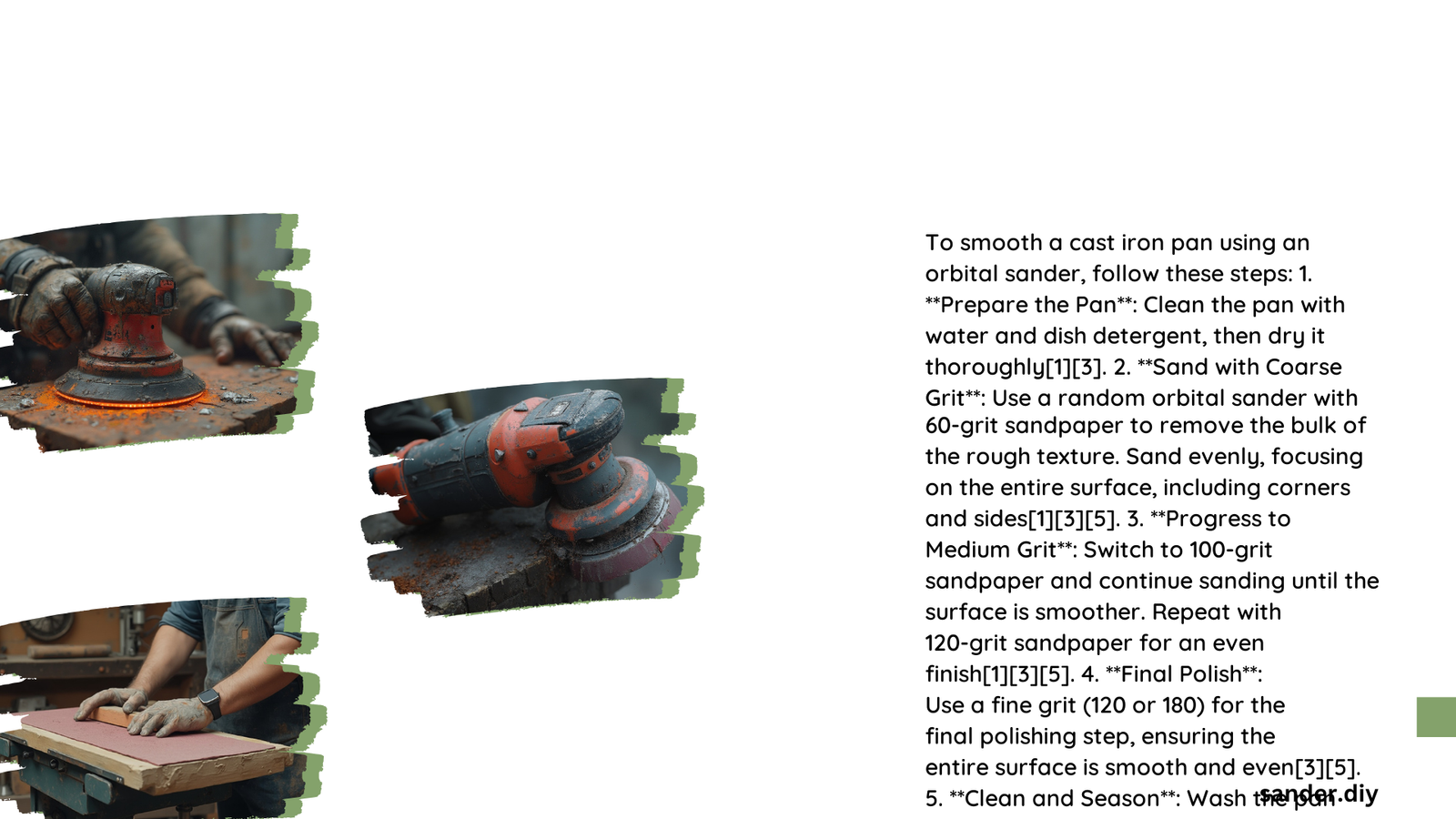

Orbital sanders excel in cast iron surface preparation due to their unique motion and controlled material removal. Unlike traditional sanders, orbital sanders move in random circular patterns, preventing repetitive scratch patterns and ensuring uniform surface treatment.

Key Advantages of Orbital Sanders on Cast Iron

| Advantage | Description | Impact |

|---|---|---|

| Uniform Surface | Random orbital motion | Prevents directional scratches |

| Dust Management | Integrated collection systems | Maintains clean workspace |

| Versatile Grit Options | Multiple sandpaper grits | Adaptable to different surface conditions |

How to Choose the Right Orbital Sander for Cast Iron?

Top Recommended Models

- Makita Five-Inch Random Orbit Sander

- Power Rating: 3 amps

- Excellent for precision work

-

Comfortable grip design

-

DeWalt 20V Cordless Orbital Sander

- Cordless convenience

- 8,000-12,000 orbits per minute

-

Lightweight and portable

-

Bosch ROS20VSC Random Orbital Sander

- 2.5 amps power

- Smooth random orbital motion

- High-performance dust collection

What Grit Progression Works Best?

Recommended Sanding Strategy

- Coarse Grit (80-100): Initial rust and rough surface removal

- Medium Grit (120-150): Surface smoothing

- Fine Grit (220-240): Final finishing and polishing

How to Achieve Professional Results?

Critical Techniques

- Speed Control: Maintain 8,000-12,000 orbits per minute

- Pressure Application: Use moderate, consistent pressure

- Movement Pattern: Systematic back-and-forth or circular motion

- Dust Management: Always use vacuum or dust collection system

What Safety Precautions Should You Follow?

Essential Safety Guidelines

- Wear protective eyewear

- Use dust mask

- Ensure proper ventilation

- Check sander condition before use

- Disconnect power when changing accessories

Pro Tips for Optimal Cast Iron Sanding

- Always start with the least aggressive approach

- Test sander on small, inconspicuous area first

- Replace sandpaper when it becomes worn

- Clean surface between grit progressions

- Use light, consistent pressure

Common Mistakes to Avoid

- Applying excessive pressure

- Using incorrect grit sequence

- Neglecting dust collection

- Rushing the process

- Ignoring surface preparation

Maintenance and Care

- Clean sander after each use

- Inspect power cord and connections

- Store in dry, protected environment

- Regularly replace sandpaper and dust collection bags

Conclusion

Mastering orbital sander techniques on cast iron requires practice, patience, and understanding of both tool and material characteristics. By following professional guidelines and investing in quality equipment, you can achieve exceptional surface preparation results.