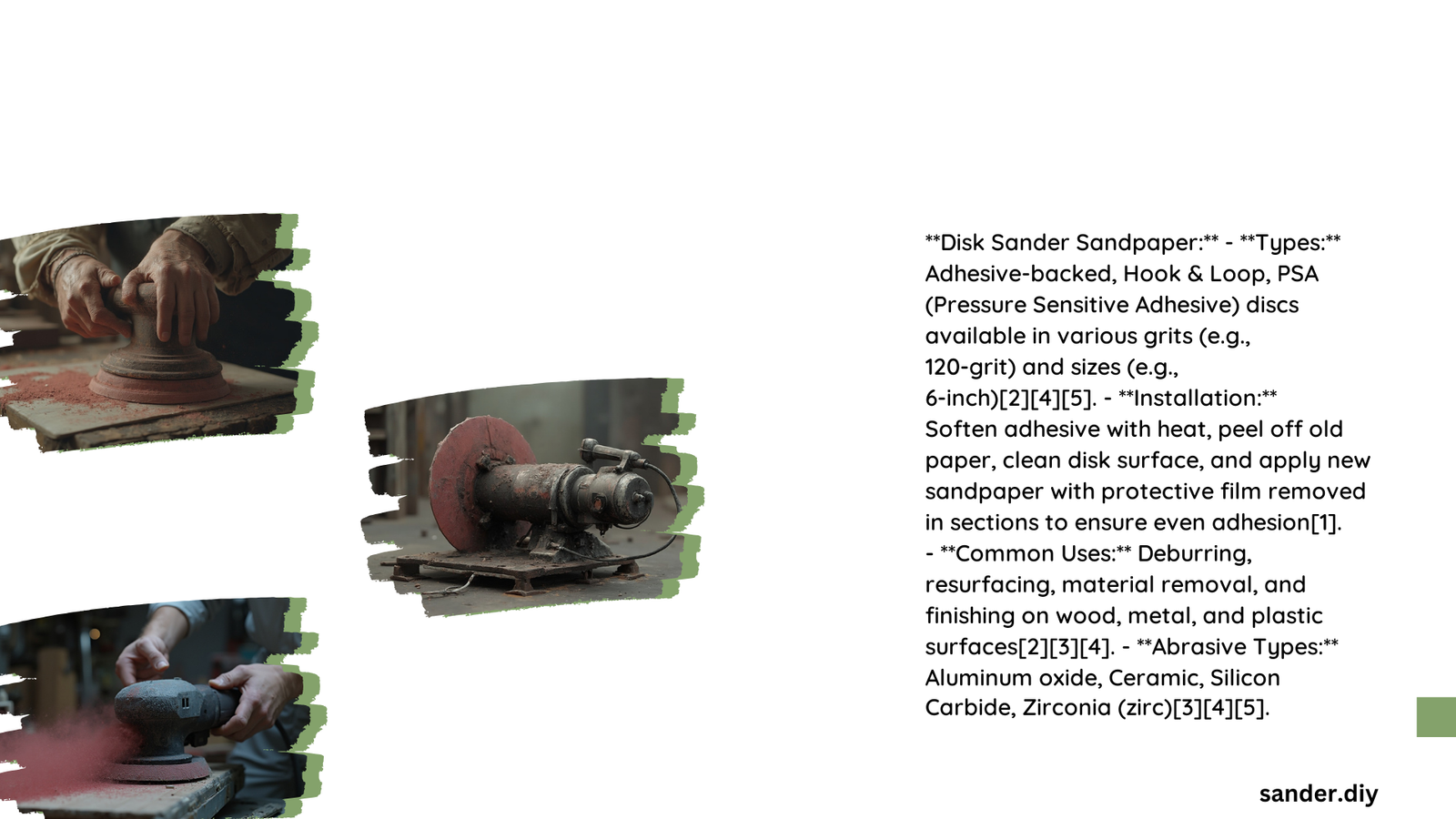

Disk sander sand paper is a critical component in achieving smooth, precise surfaces across various materials. Professional craftsmen and DIY enthusiasts rely on specialized sandpaper to transform rough surfaces into polished masterpieces. Understanding the nuanced characteristics of different grit sizes, materials, and applications can dramatically improve sanding performance and project outcomes.

What Are the Essential Grit Sizes for Disk Sander Sand Paper?

Coarse Grit Ranges: Heavy Material Removal

- 24-60 Grit Range

- Ideal for aggressive material removal

- Perfect for initial surface preparation

- Recommended for:

- Removing old paint

- Shaping wood surfaces

- Eliminating rust and rough edges

Medium Grit Ranges: Smoothing Surfaces

- 80-120 Grit Range

- Versatile sanding performance

- Excellent for intermediate surface refinement

- Best used for:

- Smoothing initial imperfections

- Preparing surfaces for fine finishing

- Balancing material removal and surface quality

Fine Grit Ranges: Precision Finishing

- 150-240 Grit Range

- Delivers ultra-smooth surface results

- Prepares surfaces for painting or staining

- Optimal for:

- Final surface preparation

- Eliminating minor scratches

- Creating professional-grade finishes

Which Sandpaper Materials Work Best for Disk Sanders?

| Material Type | Durability | Primary Applications | Cost Effectiveness |

|---|---|---|---|

| Aluminum Oxide | Moderate | Wood, Metal | High |

| Ceramic | High | Heavy-Duty Sanding | Medium-High |

| Silicon Carbide | High | Metal, Plastic | Medium |

| Garnet | Low | Hand Sanding Wood | Low |

How to Choose the Right Disk Sander Sand Paper?

Compatibility Considerations

- Match disc size to sander specifications

- Verify attachment method (hook & loop vs. adhesive)

- Check dust collection hole patterns

- Consider material-specific requirements

Performance Optimization Tips

- Start with coarser grits for initial material removal

- Progressively move to finer grits for smoother finishes

- Match sandpaper material to specific project needs

- Replace sandpaper regularly to maintain cutting efficiency

Expert Recommendations for Disk Sander Sand Paper Selection

Professional Insights

- For woodworking: Aluminum oxide sandpaper (80-220 grit)

- For metalworking: Ceramic or silicon carbide (60-400 grit)

- For automotive refinishing: High-grit silicon carbide (400-2000 grit)

Cost-Performance Balance

- Invest in quality sandpaper for consistent results

- Purchase variety packs to experiment with different grits

- Consider bulk purchasing for long-term savings

Maintenance and Storage Guidelines

Sandpaper Preservation

- Store in cool, dry environments

- Avoid direct sunlight exposure

- Use protective cases for specialized discs

- Clean sanders between grit transitions

Safety Recommendations

- Wear appropriate personal protective equipment

- Ensure proper ventilation during sanding

- Inspect sandpaper for damage before use

- Follow manufacturer’s guidelines for specific sanders

Practical Applications Across Industries

- Woodworking: Furniture refinishing, cabinetry

- Automotive: Body work, paint preparation

- Metal Fabrication: Surface smoothing, rust removal

- Construction: Floor preparation, restoration projects

Common Mistakes to Avoid

- Using incorrect grit for specific materials

- Applying excessive pressure during sanding

- Neglecting dust collection and safety protocols

- Using worn-out sandpaper

Technical Specifications Snapshot

- Average Disc Diameter: 5-9 inches

- Typical Grit Range: 24-2000

- Standard Attachment: Hook & loop, adhesive backing

- Material Compatibility: Wood, metal, plastic, composites

Reference:

– Grainger KnowHow – Sandpaper Guide

– CTW International – Sanding Disc Selection

– Empire Abrasives – Sandpaper Grit Explained