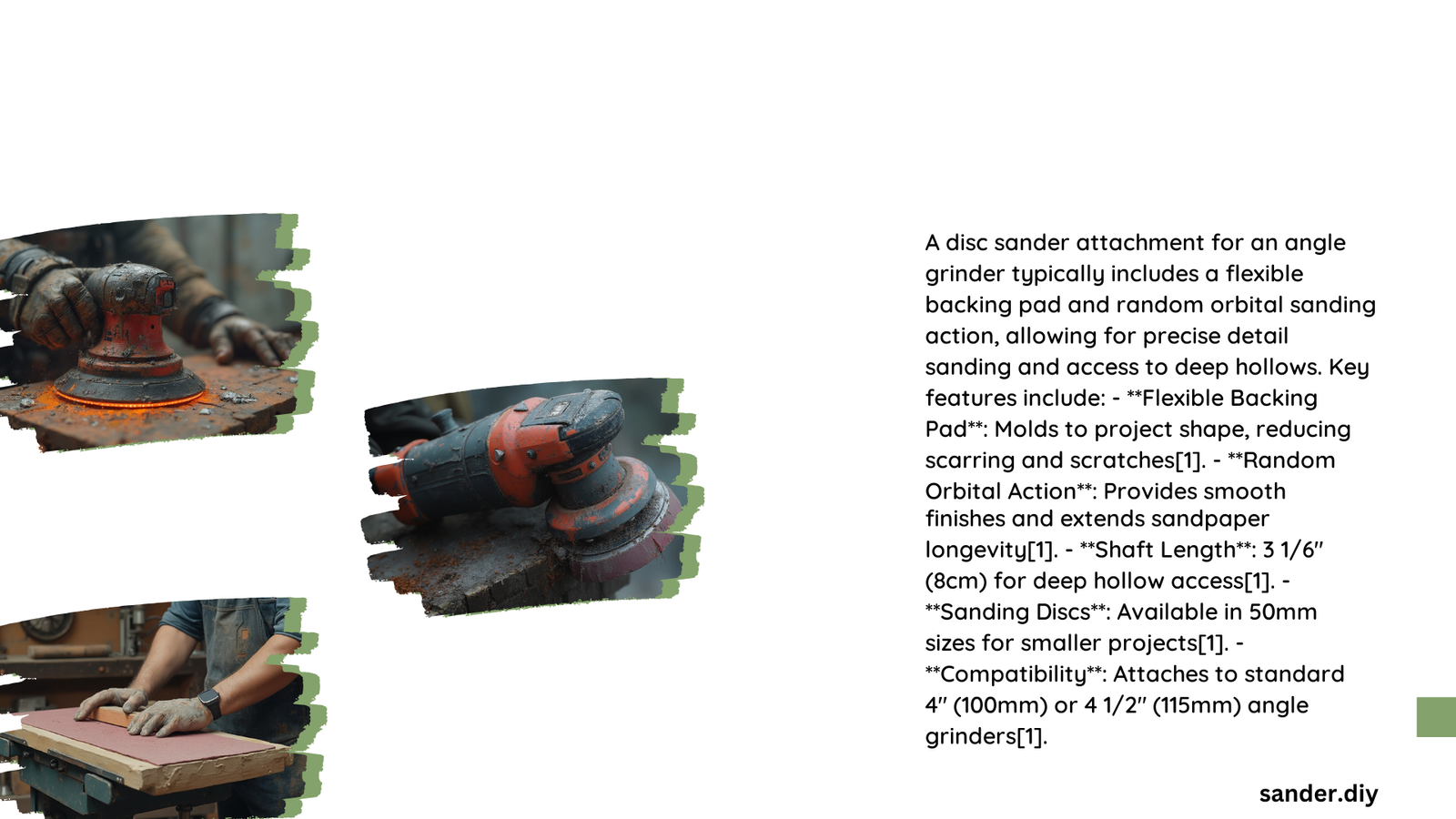

A disc sander attachment for angle grinder is a versatile accessory that transforms your angle grinder into a powerful sanding tool. It allows for efficient material removal, surface preparation, and finishing on various materials. This attachment typically consists of a backing pad and interchangeable sanding discs, offering flexibility in grit sizes for different applications.

What is a Disc Sander Attachment for Angle Grinder?

A disc sander attachment for angle grinder is an accessory that converts your angle grinder into a high-speed sanding tool. It consists of:

- A backing pad that attaches to the grinder’s arbor

- Interchangeable sanding discs of various grits

- A locking mechanism to secure the disc

This attachment allows you to perform sanding tasks with the power and speed of an angle grinder, making it ideal for large surface areas and tough materials.

How Does a Disc Sander Attachment Improve Your Angle Grinder?

A disc sander attachment enhances your angle grinder’s capabilities in several ways:

- Versatility: Transforms your grinder into a multi-purpose tool

- Efficiency: Allows for faster material removal and surface preparation

- Precision: Offers better control for fine finishing tasks

- Cost-effectiveness: Eliminates the need for a separate sanding tool

By adding this attachment, you can tackle a wider range of projects with a single power tool.

What Are the Key Features to Look for in a Disc Sander Attachment?

When selecting a disc sander attachment for your angle grinder, consider these crucial features:

- Compatibility: Ensure it fits your grinder’s arbor size and RPM rating

- Disc size: Typically 4-1/2 inches for most angle grinders

- Backing pad quality: Look for durable materials like rubber or polyurethane

- Disc changing mechanism: Easy-to-use systems for quick disc swaps

- Dust collection capability: Some attachments offer dust extraction ports

A high-quality attachment will provide better performance and longevity.

How to Install a Disc Sander Attachment on Your Angle Grinder?

Follow these steps to install a disc sander attachment:

- Unplug the angle grinder for safety

- Remove any existing attachments or discs

- Attach the backing pad to the grinder’s arbor

- Secure the backing pad with the provided locknut

- Align and attach the sanding disc to the backing pad

- Tighten the disc securely using the attachment’s locking mechanism

Always refer to the manufacturer’s instructions for specific details.

What Materials Can You Sand with a Disc Sander Attachment?

A disc sander attachment is versatile and can be used on various materials:

| Material | Recommended Grit Range |

|---|---|

| Wood | 60-220 |

| Metal | 36-120 |

| Plastic | 80-400 |

| Drywall | 120-220 |

| Concrete | 24-80 |

Choose the appropriate grit based on the material and desired finish.

How to Choose the Right Sanding Disc for Your Project?

Selecting the right sanding disc is crucial for optimal results. Consider:

- Grit size:

- Coarse (24-60): For heavy material removal

- Medium (80-120): For general sanding and smoothing

-

Fine (150-400): For finishing and polishing

-

Disc material:

- Aluminum oxide: Versatile and suitable for most materials

- Silicon carbide: Ideal for harder materials like metal or stone

-

Ceramic: Long-lasting and efficient for tough sanding tasks

-

Backing type:

- Paper: Economical but less durable

- Cloth: More flexible and durable

Choose discs that match your project requirements and material type.

What Safety Precautions Should You Take When Using a Disc Sander Attachment?

Safety is paramount when using a disc sander attachment. Follow these precautions:

- Wear appropriate personal protective equipment (PPE):

- Safety glasses

- Dust mask

- Hearing protection

- Work gloves

- Ensure the attachment and disc are properly secured before use

- Maintain a firm grip on the grinder with both hands

- Apply even pressure and avoid tilting the grinder

- Allow the tool to reach full speed before contacting the workpiece

- Keep the work area clean and well-ventilated

Always prioritize safety to prevent accidents and injuries.

How to Maintain Your Disc Sander Attachment for Longevity?

Proper maintenance ensures the longevity of your disc sander attachment:

- Clean the backing pad after each use to remove dust and debris

- Inspect the pad regularly for wear or damage

- Store the attachment in a dry, clean place

- Replace worn sanding discs promptly

- Lubricate moving parts as recommended by the manufacturer

- Check and tighten any loose components before each use

Regular maintenance will extend the life of your attachment and ensure consistent performance.

What Are the Limitations of Using a Disc Sander Attachment on an Angle Grinder?

While versatile, disc sander attachments have some limitations:

- Speed control: Angle grinders typically operate at high speeds, which may not be ideal for all sanding tasks

- Weight distribution: The added weight can affect balance and control

- Dust collection: Not all attachments offer efficient dust extraction

- Precision: May be less precise than dedicated sanders for fine finishing work

- Heat generation: High-speed sanding can generate excessive heat on sensitive materials

Understanding these limitations helps you use the attachment effectively and safely.

How Does a Disc Sander Attachment Compare to Other Sanding Tools?

Let’s compare the disc sander attachment to other common sanding tools:

| Tool | Pros | Cons |

|---|---|---|

| Disc Sander Attachment | – High power – Versatile – Cost-effective |

– Less precise – Limited speed control |

| Orbital Sander | – Good for fine finishing – Variable speed |

– Less aggressive – Smaller sanding area |

| Belt Sander | – Efficient for large surfaces – Good for heavy material removal |

– Can be difficult to control – Not suitable for curved surfaces |

| Hand Sanding | – Precise control – No power required |

– Time-consuming – Labor-intensive |

The disc sander attachment offers a balance of power and versatility, making it suitable for a wide range of tasks.

What Are Some Professional Tips for Using a Disc Sander Attachment?

To get the most out of your disc sander attachment, consider these professional tips:

- Start with a coarser grit and progressively move to finer grits for a smooth finish

- Keep the sander moving to avoid creating uneven spots or gouges

- Use light to moderate pressure; let the tool do the work

- Clean or change discs frequently to maintain optimal performance

- Practice on scrap material to get a feel for the tool’s behavior

- Use a dust extraction system for cleaner and healthier working conditions

- Allow the workpiece to cool between passes to prevent heat damage

These tips will help you achieve professional-quality results with your disc sander attachment.

By following this comprehensive guide, you’ll be well-equipped to choose, use, and maintain a disc sander attachment for your angle grinder effectively and safely.

References:

1. https://www.homedepot.com/p/DIABLO-4-1-2-in-Grinder-to-Sander-Conversion-Kit-DCP045VGPS01G/202830887

2. https://forum.swaylocks.com/t/converting-a-grinder-to-a-sander/48909

3. https://www.dewalt.com/products/power-tools/grinders-polishers/grinder-attachments-accessories