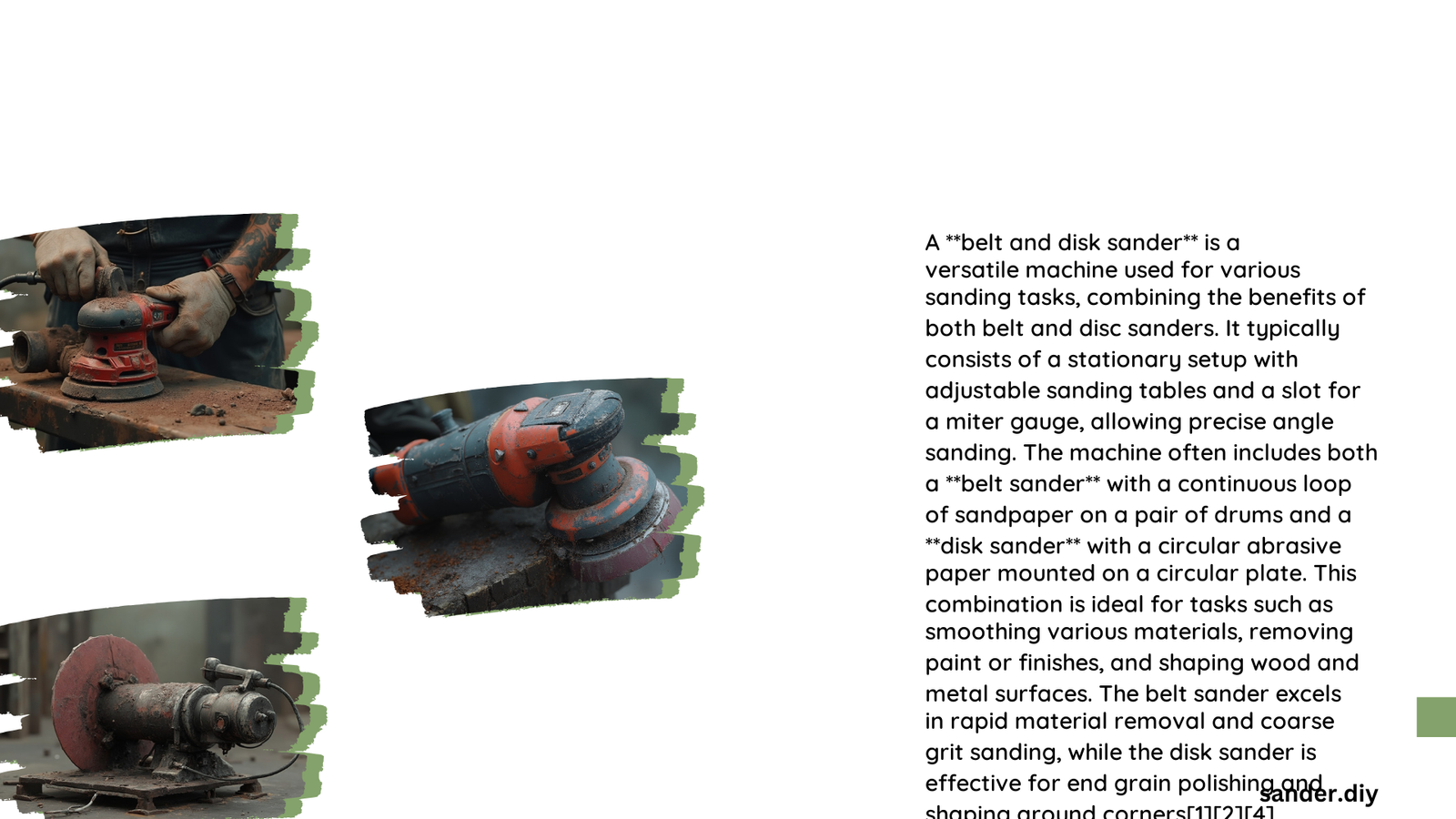

A belt and disk sander represents a powerful, dual-function woodworking machine that combines two distinct sanding mechanisms in a single unit. This versatile tool integrates a horizontal belt sander for large, flat surface processing and a vertical disk sander for curved and angular material preparation, enabling woodworkers and craftsmen to achieve precise surface finishing with enhanced efficiency and flexibility across various material types and project requirements.

What Is a Belt and Disk Sander?

A belt and disk sander is a specialized power tool designed to provide multiple sanding capabilities in one compact machine. By integrating two distinct sanding surfaces, this equipment offers woodworkers and craftsmen unprecedented versatility in surface preparation and finishing tasks.

Key Components of Belt and Disk Sanders

| Component | Description | Typical Specifications |

|---|---|---|

| Belt Sander | Horizontal sanding surface | 4″-6″ width, 36″-48″ length |

| Disk Sander | Vertical circular sanding surface | 6″-12″ diameter |

| Motor | Powers both sanding mechanisms | 1/2 HP – 1.5 HP |

How Does a Belt and Disk Sander Work?

Belt Sander Mechanism

- Continuous abrasive belt moves at high speed

- Allows linear sanding of flat surfaces

- Adjustable angle for versatile positioning

- Typical speeds: 1,900-2,690 surface feet per minute

Disk Sander Mechanism

- Circular abrasive disk rotates at high RPM

- Ideal for curved and angular surface finishing

- Tilting table enables precise angle adjustments

- Typical speeds: 2,630-3,450 rotations per minute

What Are the Primary Applications?

Wood Processing

- Smoothing rough lumber surfaces

- Preparing edges and corners

- Removing old finishes

- Shaping wooden components

Material Compatibility

- Solid wood

- Plywood

- Engineered wood products

- Soft metals (with appropriate abrasives)

- Plastic materials

Technical Performance Factors

Performance Metrics

- Grit Range: 80-320 grit

- Power Requirements: 120V-230V

- Motor Amperage: 4.3-14 amps

- Dust Collection: Integrated ports (2.5″-4″ diameter)

Selecting the Right Belt and Disk Sander

Considerations for Purchase

- Motor power

- Belt/disk size

- Table tilt range

- Dust collection efficiency

- Intended project requirements

Maintenance and Care

Recommended Practices

- Regular abrasive belt/disk replacement

- Consistent dust port cleaning

- Lubrication of moving parts

- Proper storage in dry environment

Safety Recommendations

Essential Protective Gear

- Safety glasses

- Dust mask

- Hearing protection

- Close-fitting work clothing

Conclusion

Belt and disk sanders represent sophisticated woodworking tools that combine multiple sanding functions, offering professionals and hobbyists unprecedented surface preparation capabilities. Understanding their technical specifications and operational nuances ensures optimal performance and longevity.

Pro Tips

- Always match abrasive grit to specific material

- Maintain consistent pressure during sanding

- Use appropriate safety equipment

- Regular maintenance extends tool life