When tackling rust removal from metal surfaces, selecting the right sander is crucial for achieving professional results. Metal rust can compromise structural integrity and appearance, making effective removal essential for maintenance, restoration, and preparation of metal surfaces. The optimal sander depends on the specific metal type, rust severity, and desired finish, with orbital sanders emerging as the most versatile and recommended tool for comprehensive rust elimination.

What Makes a Sander Effective for Rust Removal?

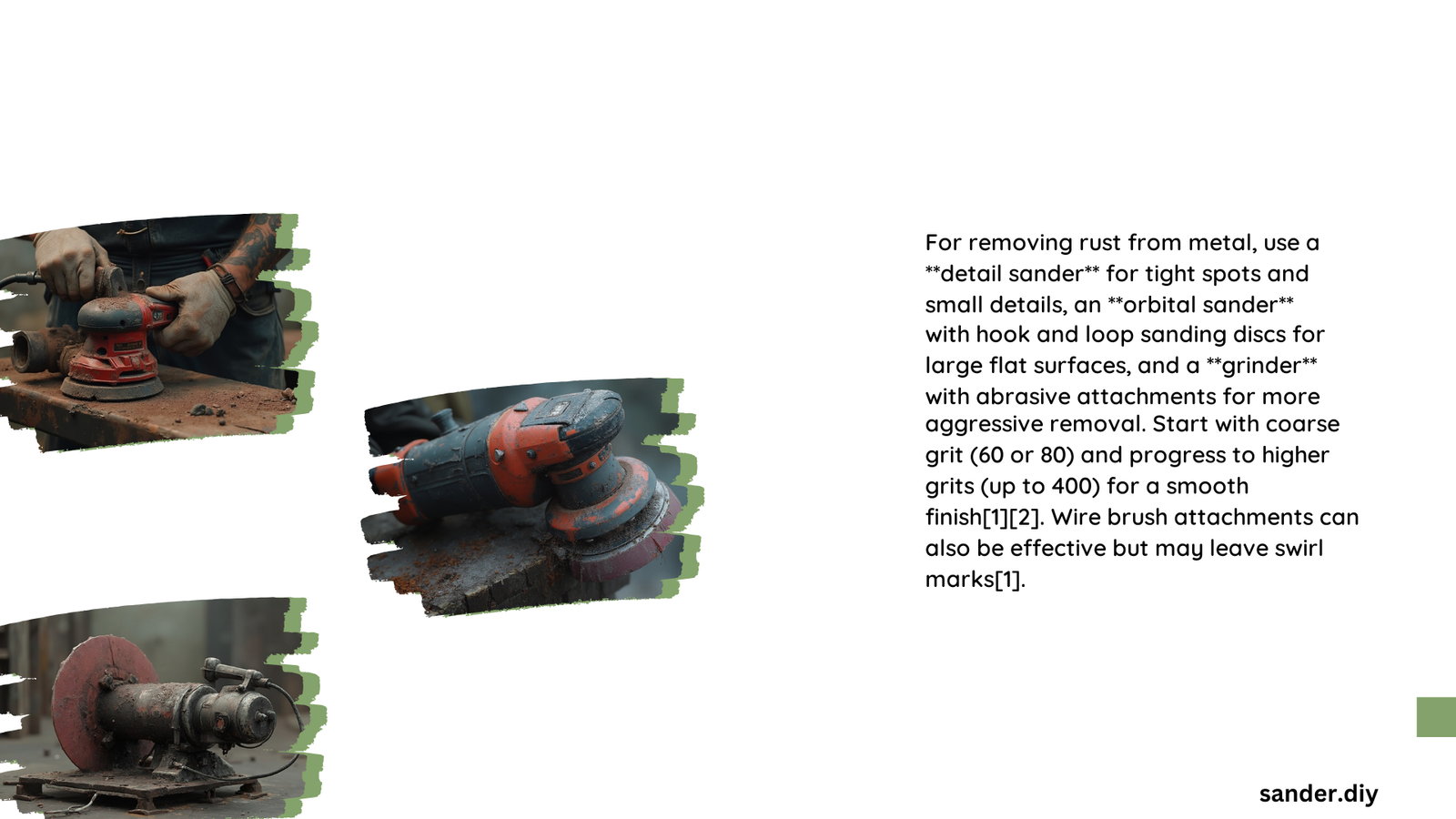

Rust removal requires precision, power, and controlled abrasion. Different sanders offer unique advantages in addressing metal surface corrosion. Understanding these characteristics helps professionals and DIY enthusiasts choose the most appropriate tool.

Key Characteristics of Rust Removal Sanders

| Sander Type | Rust Removal Efficiency | Surface Control | Recommended Applications |

|---|---|---|---|

| Orbital Sanders | High | Excellent | General metal surfaces, detailed work |

| Belt Sanders | Moderate | Limited | Large, flat metal areas |

| Angle Grinders | Very High | Low | Heavy rust, industrial applications |

Why Choose an Orbital Sander for Rust Removal?

Orbital sanders provide unparalleled versatility in rust elimination. Their unique oscillating motion prevents aggressive material removal while ensuring comprehensive rust coverage. Key benefits include:

- Consistent Surface Preparation: Reduces risk of uneven sanding

- Minimal Metal Damage: Controlled abrasion prevents excessive material loss

- Dust Collection: Integrated systems maintain clean working environments

What Sandpaper Grit Should You Use?

Selecting appropriate sandpaper grit is critical for effective rust removal:

- Coarse Grits (40-80): Initial rust layer removal

- Medium Grits (120-180): Smoothing surface imperfections

- Fine Grits (220-400): Final surface refinement

How to Prepare Metal Surfaces for Sanding?

Proper preparation maximizes rust removal efficiency:

- Clean surface with degreaser

- Apply rust-loosening lubricant

- Wear protective equipment

- Ensure proper workspace ventilation

What Techniques Enhance Rust Removal?

Professional rust removal involves strategic approaches:

- Use light, consistent pressure

- Move sander in multiple directions

- Periodically check surface temperature

- Use dust extraction systems

- Replace sandpaper frequently

Recommended Sanders for Different Rust Scenarios

Light Rust Removal

- Recommended: Random Orbital Sander

- Grit Range: 120-180

- Technique: Gentle, overlapping movements

Heavy Rust Removal

- Recommended: Belt Sander or Angle Grinder

- Grit Range: 40-80

- Technique: Aggressive, controlled passes

Safety Considerations

- Wear safety glasses

- Use respiratory protection

- Work in well-ventilated areas

- Disconnect power before changing accessories

Professional Tips

- Invest in quality sanders with variable speed controls

- Use ceramic or aluminum oxide sandpaper

- Maintain consistent sanding pressure

- Clean surface between grit progressions

Cost-Effective Recommendations

| Budget Level | Recommended Sander | Price Range |

|---|---|---|

| Budget | Black & Decker Orbital Sander | $50-$80 |

| Mid-Range | DeWalt Random Orbital Sander | $100-$150 |

| Professional | Bosch Professional Sander | $200-$300 |

Final Considerations

Successful rust removal requires understanding your specific metal surface, rust condition, and desired outcome. Experiment with techniques and always prioritize safety and precision.

Reference:

– Rust Removal Techniques

– Professional Sanding Guide

– Metal Surface Preparation